K-FLEX Energo

Reliable and quick installation of technical insulation systems using K-FLEX Energo materials can significantly reduce labor costs during thermal insulation work.

Reliable and quick installation of technical insulation systems using K-FLEX Energo materials can significantly reduce labor costs during thermal insulation work.

allows to significantly reduce labor costs during thermal insulation work.

It can be used in the constRusction of thermal insulation of equipment and pipelines of industrial facilities, as well as housing and communal services, including:

• Flange connections of pipelines, coupling and flange fittings;

• Reservoirs for storing water in water supply systems and fuel oil at thermal power plants;

• Laying outdoors is possible, subject to the use of coatings that protect the surface of products from ultraviolet exposure.

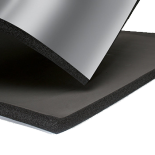

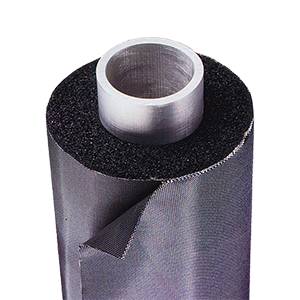

Aluminum Foil Coated Rolls

Rolls coated with polypropylene, aluminum foil and PET film

Fiberglass coated rolls

Rolls with a polymer coating of black or gray color K-FLEX thermal insulation with negative temperatures

• heating network;

• containers;

• technological pipelines;

• heating;

• water supply;

• refrigeration industry;

• Temperature range: -200°C to +105°C

• Thermal conductivity 1W: 0.024 to 0.039

• Humidity resistance: >7,000

• Sound insulation, dB (A): Up to 32

• Density, kg/m3: From 65 to 80

• Toxicity: Free of CFCs, HCFCs

• Biological stability: Good

• Oil petrol resistance: Good

• heating network;

• process tanks and pipelines;

• low pressure steam pipelines;

• boiler houses, CHP, CHP

• Temperature range: up to +180°C (short-term, up to a day) 150°C permanently

• Thermal conductivity 1W: 0.038 to 0.043

• Humidity resistance: >4000

• Fire safety: G1, RP1

• Sound insulation, dB (A): Up to 32

• Density, kg/m3: From 70 to 900

• Toxicity: Free of CFCs, HCFCs

• Biological stability: Good

• Oil petrol resistance: Good